The Automotive acrylic foams are well-known for their viscoelasticity that allows an insuperable sealing of different surfaces.

The acrylic foams have many advantages , both in terms of application and in the final performance. For example, they allow high resistance fixing and sealing together with vibration and sound absorbing properties.

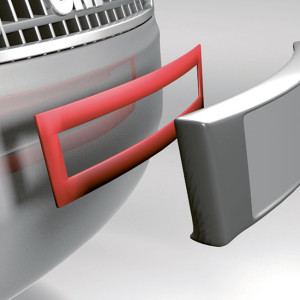

Thanks to acrylic foams you do not have to hole the metal plate, you don’t have any risks of corrosion and you will get perfect fixing lines, with aesthetics and aerodynamic advantages.

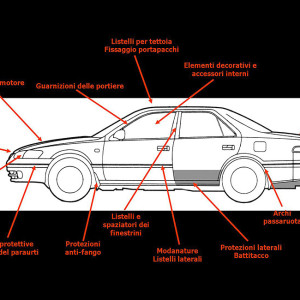

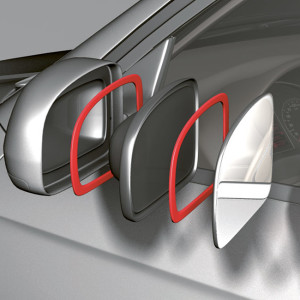

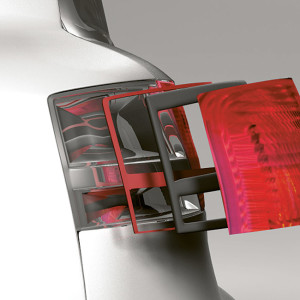

In the automotive field, the acrylic foams are used for fixing indoor or outdoor components such as door gaskets, wheel arch, moldings, emblems, lights, decorative elements and internal accessories.

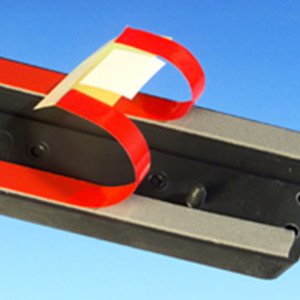

These products can be provided in cut rolls in different sizes, or die-cut according to customer’s specifications.

The wide range of existing products is able to meet any needs: products for high and low energy surfaces, white, grey, black or transparent foams, different thickness from 0,005 mm. to 3mm., foams for high and low temperatures application or for many others applications.